The science behind DispenCell

Why choose DispenCell — our award-winning single cell seeding technology?

<0.2 psi cell dispensing.

<4 min per 96 well plate.

1,000 cells processed in <1hr.

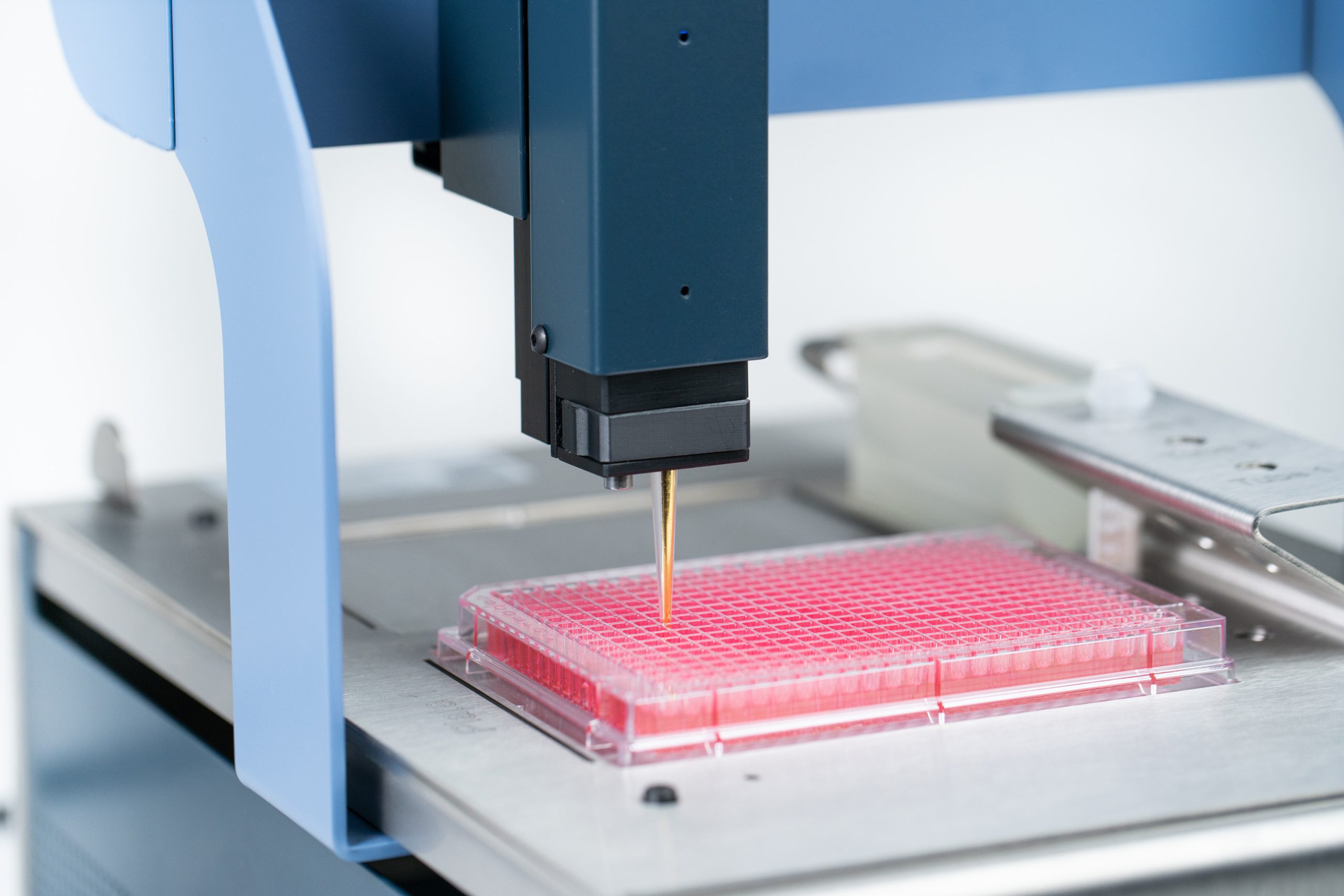

1. Patented sensing tip – Rapid one cell in the well – No cross contamination.

DispenCell is fitted with a sensing tip that acts as a Coulter counter. Cells that pass through the Coulter aperture to flow into the well leave electrical signatures that appear as peaks and are immediately recorded. A single unique peak indicates that there is only one cell in the well — several peaks mean multiple cells and a small peak is a mark of debris. DispenCell’s tip is disposable, which ensures no cross contamination.

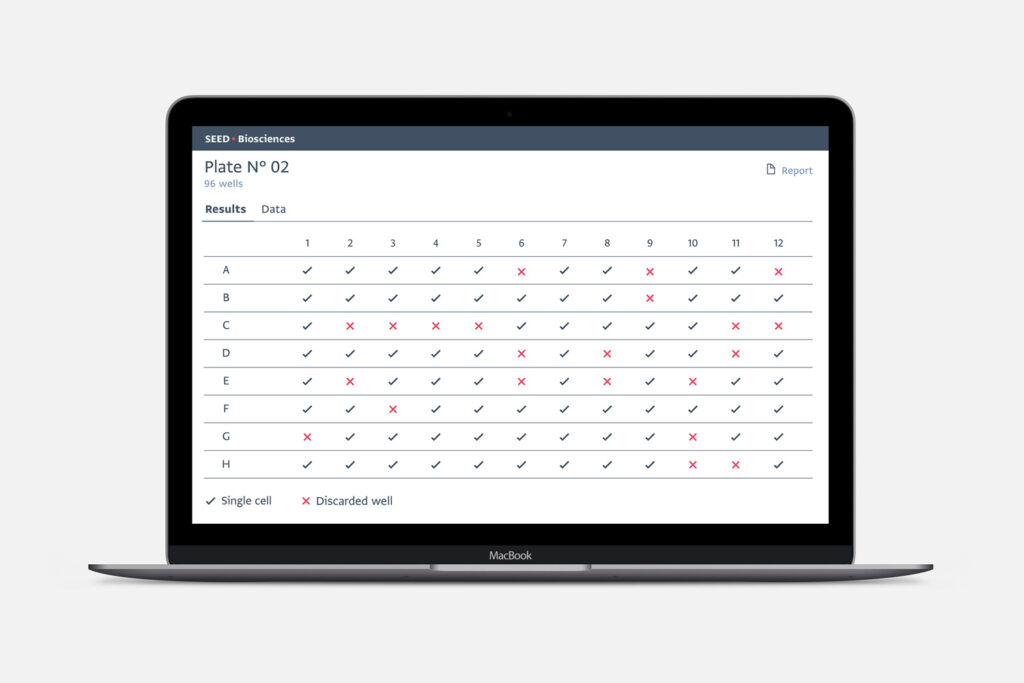

2. Instant proof of monoclonality.

At the end of the experiment, the electrical signatures are examined in detail. Wells that do not meet the quality control criteria, such as those with multiple cells or debris, are rejected. The full set of data is stored in a report, allowing the user to instantly check for monoclonality.

3. As gentle as a human hand, with robotic speed.

DispenCell’s patented tip is designed with impedance-based cell seeding technology, which allows extremely gentle handling that is comparable to manual pipetting, yet much faster. DispenCell dispenses cells with <0.2 psi pressure, which protects cell viability and outgrowth. The robotic speed of DispenCell allows cells to be pipetted into a 96 well plate in less than 4 minutes — meaning 1,000 cells can be processed in less than an hour. DispenCell’s core technology has been developed and patented at the Ecole Polytechnique Fédérale de Lausanne (EPFL).

Learn more about DispenCell’s award-winning single cell seeding technology in its application notes.